MODEL #113

Scale Controlled Liquid Fillers

DESCRIPTION:

Available in single and dual station models, featuring stainless steel construction and the latest digitally controlled scales for an extremely accurate fill. Customized solutions available to fit your exact needs.

PERFECT FOR:

Liquid or similar self leveling product such as:

- Donut icing

- Glazing

- Edible oils

- Fruit flavorings

- Mayonnaise

- BBQ

- Syrups

- Dressings

- Fruit Flavors

- Yogurt

- Sour Cream

- Sauces

BENEFITS:

- Increase your production rates

- Enhance your accuracy

- Decrease your labor costs

- Full after-sales support

THIS WOULD SUIT

- Artisans

- Start-up companies

- Dairies

- Contract packers

- Commercial kitchens

- Food innovation centers

- Small, medium, large scale independent food producers

- National food groups

- 3rd party equipment suppliers

MODEL OPTIONS INCLUDE:

MODEL

#113-AAA

Scale Controlled Liquid Filler

Liquid Pail Filler

Fill-to-Weight Scale Filler

Semiautomatic Pail Filler

Triple A Filler

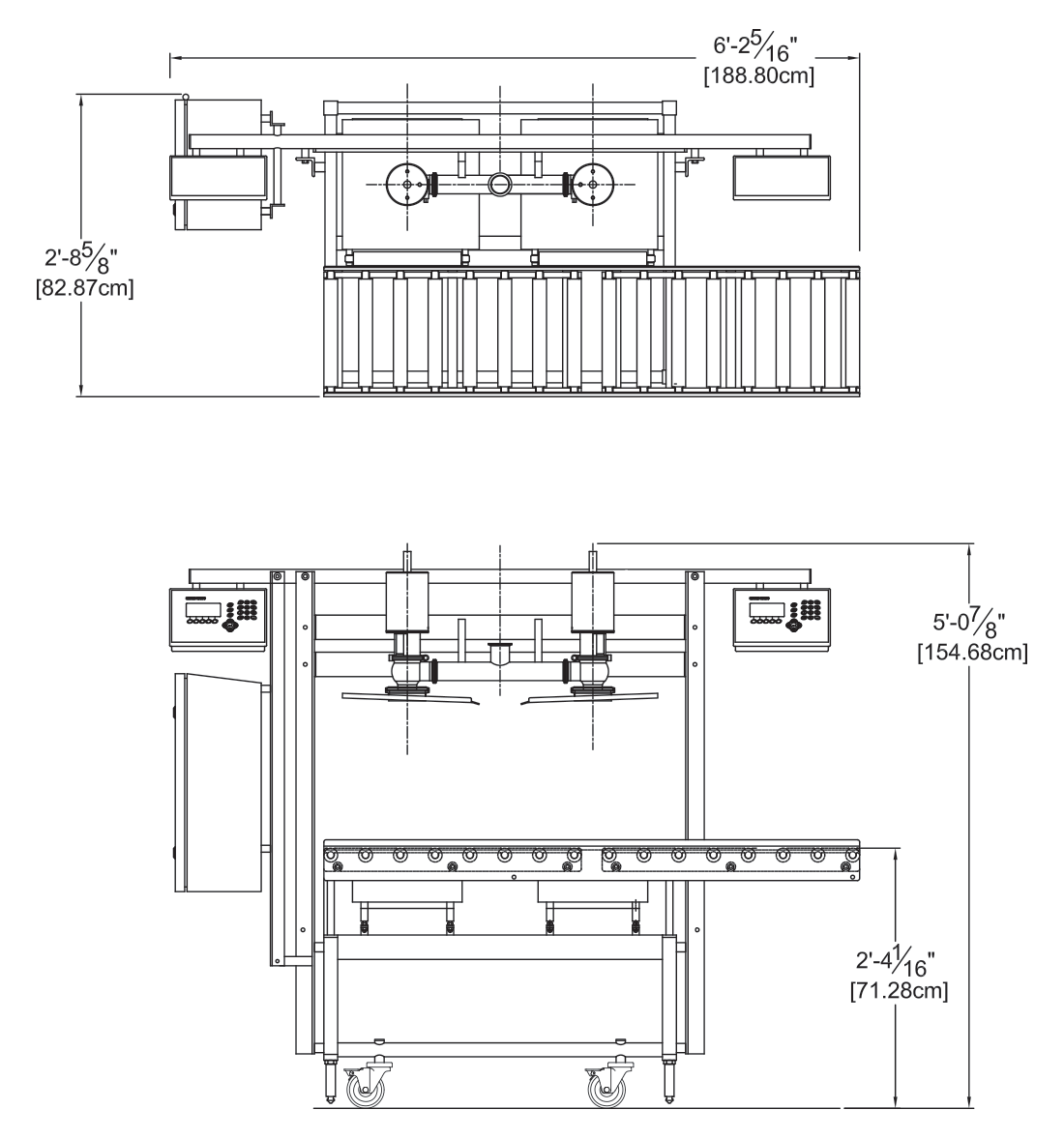

MODEL #113-AAA

MODEL #113-AAA

DESCRIPTION:

Semiautomatic dual station scale filler featuring stainless steel construction and the latest digitally controlled scale for an extremely accurate fill.

CONTAINER SIZE RANGE:

- 1 gallon, 2 gallon, 2.5 gallon, 3 gallon, 3.5 gallon, 4 gallon, 5 gallon, 6 gallon

- 4 liter, 5 liter, 6 liter, 10 liter, 11 liter, 15 liter, 20 liter

- 30 lb bag in box, 40 lb bag in box, 50 lb bag in box, 55 lb bag in box

- 5 gallon jug in box (JIB)

FEATURES AND BENEFITS

KEY FEATURES:

- Sawvel’s “Triple A” rated equipment is designed to meet a higher sanitary standard

- Continuous product flow, alternating side to side

- Dual electronic weighing system provides highest possible filling accuracy

- 3-A® approved filling valves rated for CIP cleaning

- Fills plastic pails and/or bag-in-box containers

- Throttle down final fill

- Quick tooling change for additional sizes

- Right or left hand operation

- Stainless steel casters and leveling screws

- Speeds to 8 cpm (see options)

- 304 stainless steel construction

- Compact footprint

OPTIONS AVAILABLE:

- Larger fill valve assemblies in 2.0”, 2.5” and 3.0” sizes

- Tooling for additional container sizes

- Powered outfeed conveyor; increases speeds to 12 cpm

- Automatic denesting

- Automatic lidding

SAWVEL AAA:

This model has been designed to meet or exceed 3-A®, FSMA and USDA sanitary requirements.

- All materials rated for food contact

- Full disassembly for cleaning can be done without tools

- Elimination of flat surfaces provides excellent drainage after clean up

- Elimination of all points that could not be accessed for cleaning

QUICK CHANGE TOOLING:

Less than 5 minutes to change over from pails to bag-in-box.

- Allows for flexible production planning

CONTINUOUS PRODUCT FLOW:

Product flow alternates back and forth between the two fill stations.

Product can be supplied with either gravity or positive pump.

- Increases through-put, highly efficient

- Allows use of positive pump for product supply

DUAL ELECTRONIC WEIGHING SYSTEM:

Two electronic scale controllers with high sample rates are used.

- Provides reliable highly accurate weight control

- Dual scale system allows continuous fill process with highest possible efficiency

THROTTLE DOWN FINAL FILL:

When the primary container is nearly full the second fill valve opens allowing product to flow into the next container. This reduces the product flow rate to the primary container prior to final cut-off.

- Provides highly accurate final weight

COMPACT FOOTPRINT:

- Saves valuable floor space

- Keeps price affordable

- Easily moved

SPECIFICATIONS

AND ELEVATION DRAWING

Air Requirements: 5 cfm @ 80 psi

Electrical Requirements: 110V AC, 5 amp, 60 Hz

Shipping Weight: 950 lbs

Width: 2’ 8 5/8” (82.57 cm)

Length: 6’ 2 5/16” (188.80 cm)

QUESTIONS?

LET’S START A CONVERSATION.

We look forward to helping you identify your best path to higher profits.

Need a custom designed solution? We can help with that as well!

1.877.488.1816

MODEL

#113S-AAA

Scale Controlled Liquid Filler

Liquid Pail Filler

Fill-to-Weight Scale Filler

Semiautomatic Pail Filler

Triple A Filler

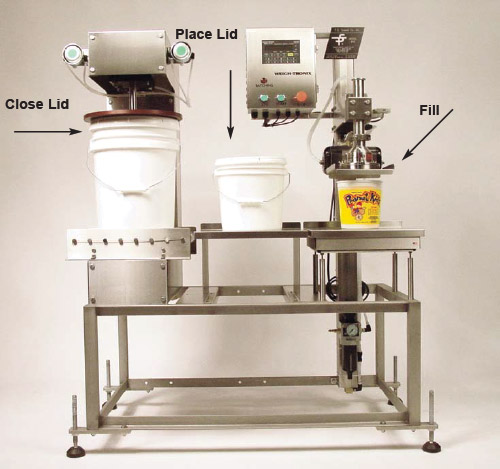

MODEL #113S-AAA

MODEL #113S-AAA

DESCRIPTION:

Single head liquid filler featuring stainless steel construction and the latest digitally controlled scale for an extremely accurate fill.

CONTAINER SIZE RANGE:

- 1 gallon, 2 gallon, 2.5 gallon, 3 gallon, 3.5 gallon, 4 gallon, 5 gallon, 6 gallon

- 4 liter, 5 liter, 6 liter, 10 liter, 11 liter, 15 liter, 20 liter

- 30 lb bag in box, 40 lb bag in box, 50 lb bag in box, 55 lb bag in box

- 5 gallon jug in box (JIB)

FEATURES AND BENEFITS

KEY FEATURES:

- Sawvel “Triple A” rated equipment is designed to meet a higher sanitary standard

- Digitally controlled electronic weighing system provides highest possible accuracy

- Fills plastic pails and/or bag-in-box containers

- 3-A® approved filling valves rated for CIP cleaning

- Drip guard over fill station and lid placement station

- Quick tooling change for additional size containers

- Convertable, right or left hand operation

- Stainless steel casters and leveling screws

- Speeds to 4 cpm

- 304 stainless steel construction

- Compact footprint

WIDE RANGE OF OPTIONS AVAILABLE:

- This fill system can be expanded as your business grows!

SAWVEL AAA:

This model has been designed to meet or exceed 3-A®, FSMA and USDA sanitary requirements.

- All materials rated for food contact

- Full disassembly for cleaning can be done without tools

- Elimination of flat surfaces provides excellent drainage after clean up

- Elimination of all points that could not be accessed for cleaning

DIGITALLY CONTROLLED ELECTRONIC WEIGHING SYSTEM:

A single electronic scale controller with high sample rates is used.

- Provides reliable highly accurate weight control

CONVERTS FROM LEFT HAND PRODUCT FLOW:

If your floor plan changes, this machine can convert in the field to match your needs.

SPECIFICATIONS

AND ELEVATION DRAWING

Air Requirements: 5 cfm @ 80 psi

Electrical Requirements: 110V AC, 1 Phase, 5 amp

Shipping Weight: 700 lbs

Width: 2’ 6” (75.9 cm)

Length: 2’ 1/4” (61.8 cm)

QUESTIONS?

LET’S START A CONVERSATION.

We look forward to helping you identify your best path to higher profits.

Need a custom designed solution? We can help with that as well!

1.877.488.1816

MODEL

#113S-K

Scale Controlled Liquid Filler

Liquid Pail Filler

Fill-to-Weight Scale Filler

Semiautomatic Pail Filler

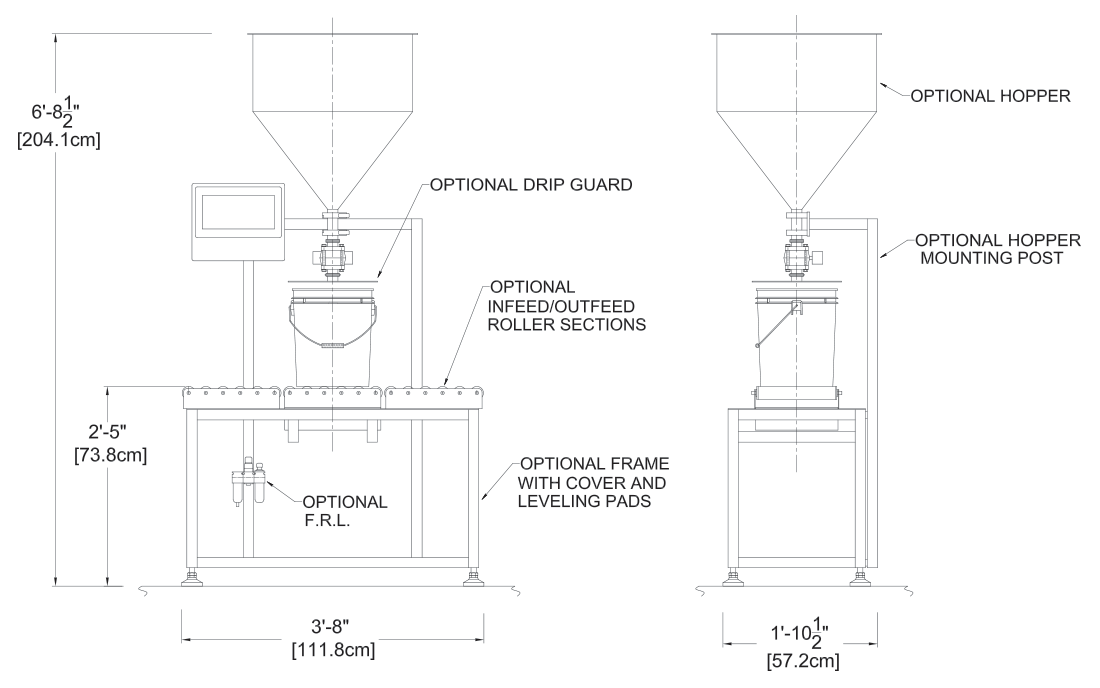

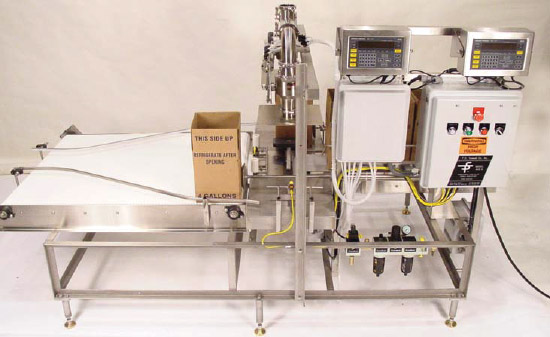

MODEL #113S-K

MODEL #113S-K

Shown with Optional Stainless Steel Frame,

Ball Valve Mount Post and Drip Guard

Also available in kit form

DESCRIPTION:

Single head liquid filler featuring stainless steel construction and the latest digitally controlled scale for an extremely accurate fill.

CONTAINER SIZE RANGE:

- 1 through 6 gallon

FEATURES AND BENEFITS

Shown with Left Hand Product Discharge and Optional

Sawvel 119 Manual Lid Press

KEY FEATURES:

- Scale controller

- Scale base, 60 lb. capacity

- Fills plastic pails and/or bag-in-box containers

- Quick tooling change for additional size containers

- Capable of integration into existing system

- 1.5” stainless steel ball valves

- Right or left hand operation

- Filter, regulator and lubricator

- Pre-wired and tested at the factory

- Speeds to 4 cpm

- 304 stainless steel construction

- Compact footprint

OPTIONS AVAILABLE:

- Larger fill valve assemblies in 2.0”, 2.5” and 3.0” sizes

- Ball valve mount posts

- Stainless steel frame with casters and leveling pads

- Roller platforms for infeed and outfeed

- Stainless steel 15 gallon hopper

- Hopper cover

- Drip guard over fill station

- Manual lid press

- Automatic lidding

SINGLE ELECTRONIC WEIGHING SYSTEM:

A single electronic scale controller with high sample rates is used.

- Provides reliable highly accurate weight control

WIDE RANGE OF OPTIONS AVAILABLE:

- This fill system can be expanded as your business grows!

BASE FILL CONFIGURATION (KIT FORM):

- Lowest possible cost for digital controlled scale system

- Allows system to be installed to fit your area

CONVERTS FROM LEFT HAND PRODUCT FLOW:

- If your floor plan changes, this machine can convert in the field to match your needs

SPECIFICATIONS

AND ELEVATION DRAWING

Air Requirements: 5 cfm @ 80 psi

Electrical Requirements: 110V AC, 1 Phase, 5 amp

Shipping Weight: 700 lbs.

Width: 1’ 10 1/2” (57.2 cm)

Length: 3’ 8” (111.8 cm)

QUESTIONS?

LET’S START A CONVERSATION.

We look forward to helping you identify your best path to higher profits.

Need a custom designed solution? We can help with that as well!

1.877.488.1816

MODEL

#113A

Scale Controlled Liquid Filler

5 Gallon Pail Filler

Fill-to-Weight Scale Filler

Liquid Pail Filler

Inline Liquid Filler

Automatic Pail Filler

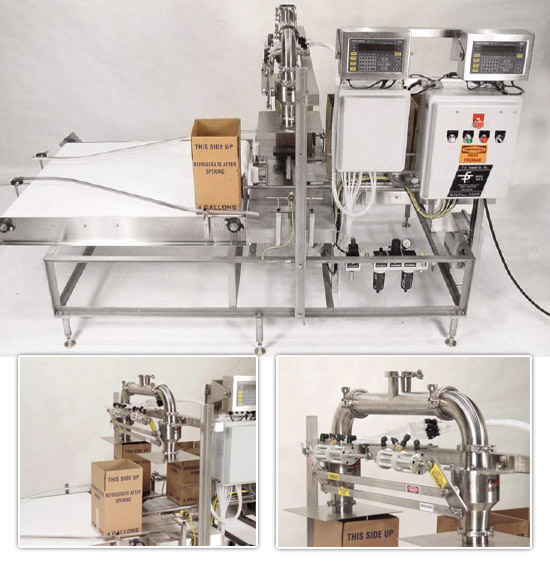

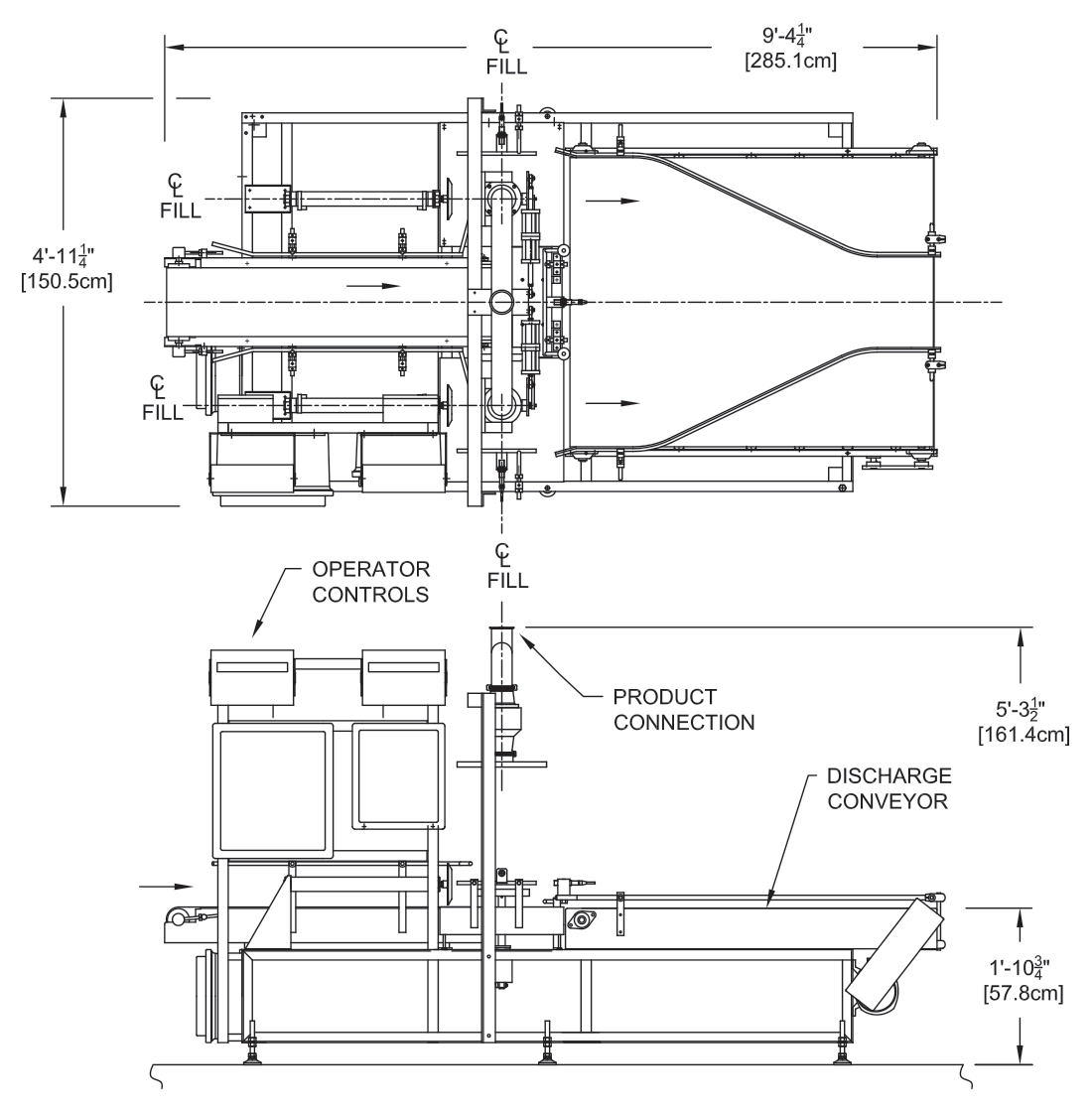

MODEL #113A

MODEL #113A

DESCRIPTION:

Automatic dual station scale filler featuring stainless steel construction and the latest digitally controlled scale for an extremely accurate fill.

CONTAINER SIZE RANGE:

- 1 through 6 gallon

FEATURES AND BENEFITS

Electronic Weighing System

3” Fill Valve Assembly

“3” Fill Valve Assembly produces continuous product fill with throttled down final fill

KEY FEATURES:

- Automatic infeed, transfer and discharge for inline operation

- Continuous product flow

- Dual electronic weighing system assuring accuracy to .3oz

- Fills plastic pails and/or bag-in-box containers

- Throttle down final fill

- Quick tooling change for additional sizes

- Capable of integration into existing system

- Right or left hand operation

- Speeds to 18 cpm, depending on product characteristic

- 304 stainless steel construction

OPTIONS AVAILABLE:

- Larger fill valve assemblies in 2.0”, 2.5” and 3.0” sizes

- Available as a complete system utilizing Sawvel denesting, lidding and conveying equipment

- Automatic no container by-pass system

- Tooling for additional container sizes

CONTINUOUS PRODUCT FLOW:

Product flow alternates back and forth between the two fill stations.

Product can be supplied with either gravity or positive pump.

- Increases through-put, highly efficient

- Allows use of positive pump for product supply

DUAL ELECTRONIC WEIGHING SYSTEM:

Two electronic scale controllers with high sample rates are used.

- Provides reliable highly accurate weight control

- Dual scale system allows continuous fill process with highest possible efficiency

THROTTLE DOWN FINAL FILL:

When the containers are nearly full the flow is split sending half to the next container reducing product flow rate prior to final cut-off.

- Provides highly accurate final weight

QUICK CHANGE TOOLING:

Less than 5 minutes to change over from pails to bag-in-box.

- Allows for flexible production planning

SPECIFICATIONS

AND ELEVATION DRAWING

Air Requirements: 10 cfm @ 80 psi

Electrical Requirements: 220V AC, 10 amp, 60 HZ

Shipping Weight: 1,005 lbs.

Width: 4’ 11 1/4” (150.1 cm)

Length: 9’ 4 1/4” (285.1 cm)

QUESTIONS?

LET’S START A CONVERSATION.

We look forward to helping you identify your best path to higher profits.

Need a custom designed solution? We can help with that as well!

1.877.488.1816

MODEL

#113 Standard

Scale Controlled Liquid Filler

Liquid Pail Filler

Fill-to-Weight Scale Filler

Semiautomatic Pail Filler

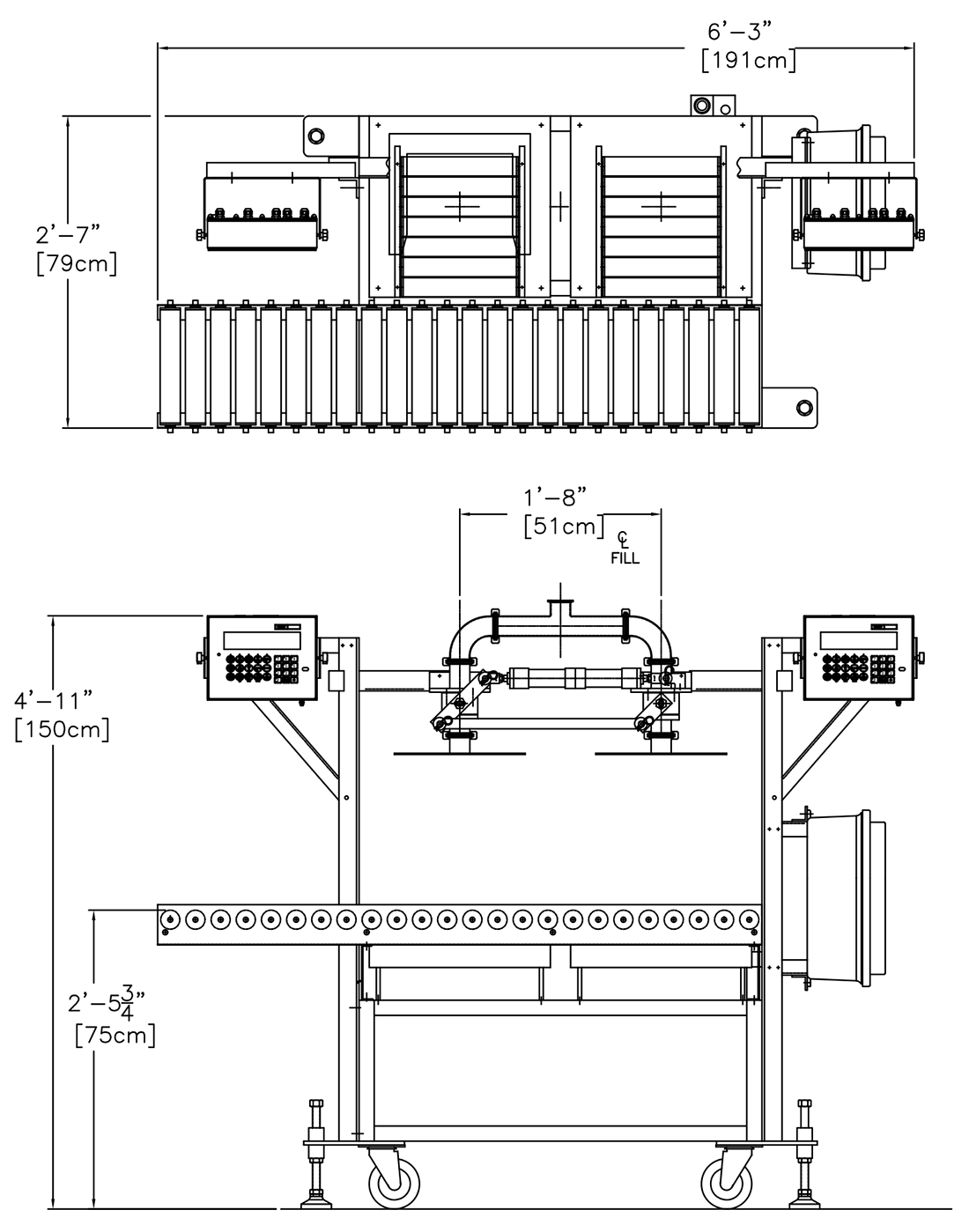

MODEL #113 STANDARD

MODEL #113 STANDARD

DESCRIPTION:

Semiautomatic dual station scale filler featuring stainless steel construction and the latest digitally controlled scale for an extremely accurate fill.

CONTAINER SIZE RANGE:

- 1 through 6 gallon

FEATURES AND BENEFITS

KEY FEATURES:

- Continuous product flow

- Dual electronic weighing system assuring accuracy to .3 oz

- Fills plastic pails and/or bag-in-box containers

- Throttle down final fill

- Quick tooling change for additional sizes

- Capable of integration into existing system

- Right or left hand operation

- Casters, jack screws and leveling pads

- Speeds to 8 cpm

- 304 stainless steel construction

- Compact footprint

OPTIONS AVAILABLE:

- Larger fill valve assemblies in 2.0”, 2.5” and 3.0” sizes

- Tooling for additional container sizes

- Powered outfeed conveyor; increases speeds to 12 cpm

- Automatic denesting

- Automatic lidding

SINGLE STATION #113 IS ALSO AVAILABLE

CONTINUOUS PRODUCT FLOW:

Product flow alternates back and forth between the two fill stations. Product can be supplied with either gravity or positive pump.

- Increases through-put, highly efficient

- Allows use of positive pump for product supply

DUAL ELECTRONIC WEIGHING SYSTEM:

Two electronic scale controllers with high sample rates are used.

- Provides reliable highly accurate weight control

- Dual scale system allows continuous fill process with highest possible efficiency

THROTTLE DOWN FINAL FILL:

When the containers are nearly full the flow is split sending half to the next container reducing product flow rate prior to final cut-off.

- Provides highly accurate final weight

COMPACT FOOTPRINT:

- Saves valuable floor space

- Keeps price affordable

- Easily moved

QUICK CHANGE TOOLING:

Less than 5 minutes to change over from pails to bag-in-box.

- Allows for flexible production planning

SPECIFICATIONS

AND ELEVATION DRAWING

Air Requirements: 5 cfm @ 80 psi

Electrical Requirements: 110V AC, 5 amp, 60 HZ

Shipping Weight: 800 lbs.

Width: 2’ 7” (78.7 cm)

Length: 4’ 6” (137.2 cm)

QUESTIONS?

LET’S START A CONVERSATION.

We look forward to helping you identify your best path to higher profits.

Need a custom designed solution? We can help with that as well!

1.877.488.1816

FREE AUTOMATION INSIGHT GUIDES

7 Ways Aging Equipment is Costing You Profits

Find out If Your Packaging Is Automation Friendly