MODEL #113A

Scale Controlled Liquid Filler / 5 Gallon Pail Filler / Fill-to-Weight Scale Filler /Liquid Pail Filler / Inline Liquid Filler / Automatic Pail Filler

DESCRIPTION:

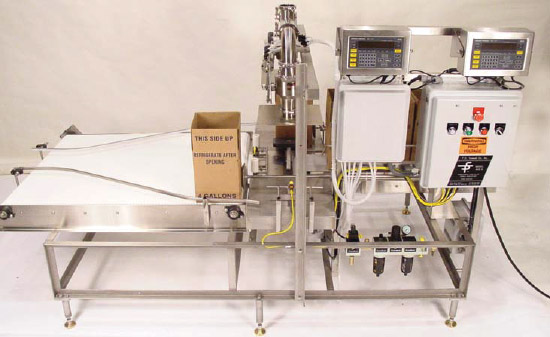

Automatic dual station scale filler featuring stainless steel construction and the latest digitally controlled scale for an extremely accurate fill.

PERFECT FOR:

Liquid or similar self leveling product such as:

- Donut icing

- Glazing

- Edible oils

- Fruit flavorings

- Mayonnaise

- BBQ

- Syrups

- Dressings

- Fruit Flavors

- Yogurt

- Sour Cream

- Sauces

CONTAINER SIZE RANGE:

- 1 through 6 gallon

THIS WOULD SUIT

- Artisans

- Start-up companies

- Dairies

- Contract packers

- Commercial kitchens

- Food innovation centers

- Small, medium, large scale independent food producers

- National food groups

- 3rd party equipment suppliers

FEATURES AND BENEFITS

Electronic Weighing System

3” Fill Valve Assembly

“3” Fill Valve Assembly produces continuous product fill with throttled down final fill

BENEFITS:

- Increase your production rates

- Enhance your accuracy

- Decrease your labor costs

- Full after-sales support

KEY FEATURES:

- Automatic infeed, transfer and discharge for inline operation

- Continuous product flow

- Dual electronic weighing system assuring accuracy to .3oz

- Fills plastic pails and/or bag-in-box containers

- Throttle down final fill

- Quick tooling change for additional sizes

- Capable of integration into existing system

- Right or left hand operation

- Speeds to 18 cpm, depending on product characteristic

- 304 stainless steel construction

OPTIONS AVAILABLE:

- Larger fill valve assemblies in 2.0”, 2.5” and 3.0” sizes

- Available as a complete system utilizing Sawvel denesting, lidding and conveying equipment

- Automatic no container by-pass system

- Tooling for additional container sizes

CONTINUOUS PRODUCT FLOW:

Product flow alternates back and forth between the two fill stations.

Product can be supplied with either gravity or positive pump.

- Increases through-put, highly efficient

- Allows use of positive pump for product supply

DUAL ELECTRONIC WEIGHING SYSTEM:

Two electronic scale controllers with high sample rates are used.

- Provides reliable highly accurate weight control

- Dual scale system allows continuous fill process with highest possible efficiency

THROTTLE DOWN FINAL FILL:

When the containers are nearly full the flow is split sending half to the next container reducing product flow rate prior to final cut-off.

- Provides highly accurate final weight

QUICK CHANGE TOOLING:

Less than 5 minutes to change over from pails to bag-in-box.

- Allows for flexible production planning

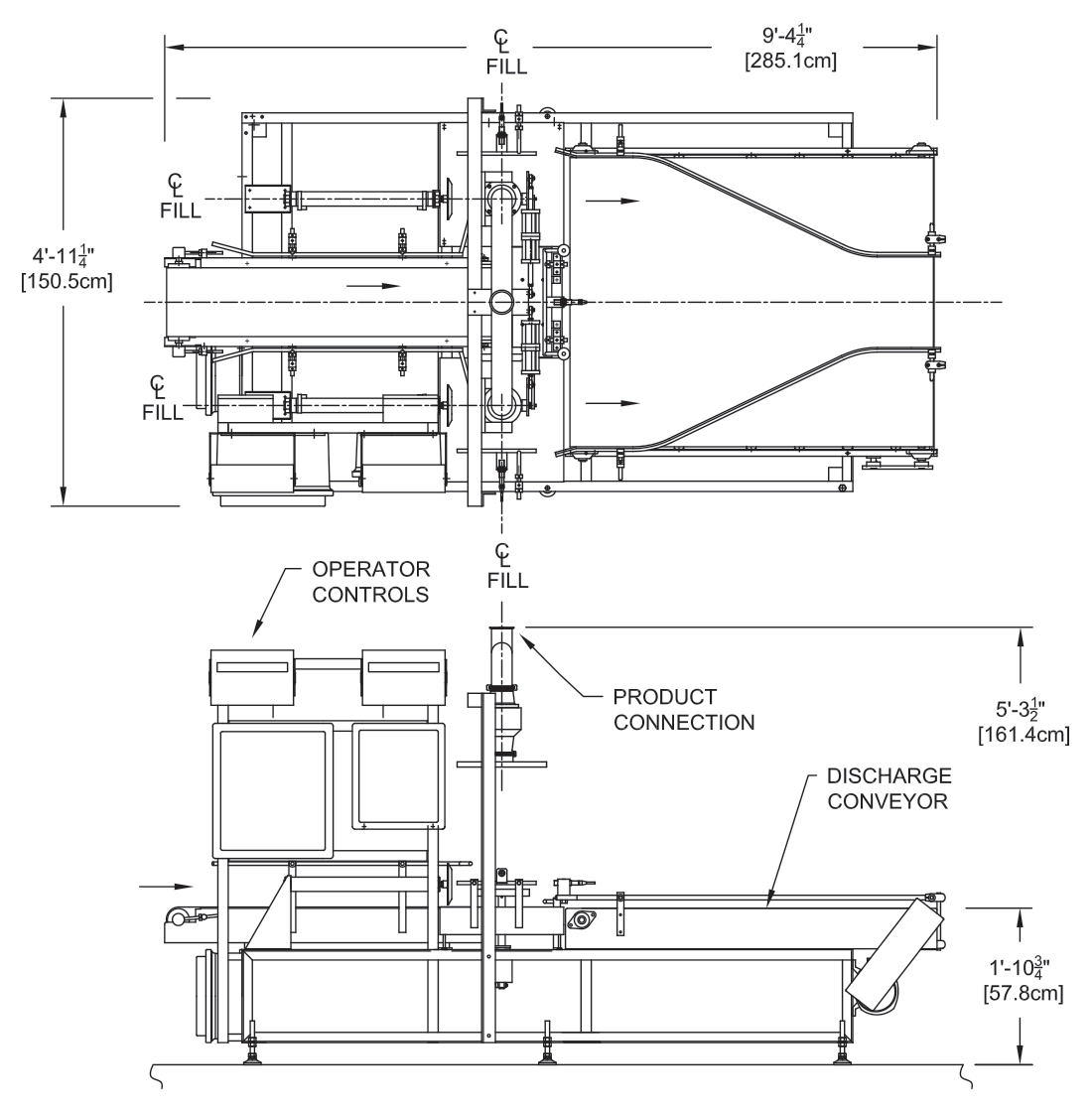

SPECIFICATIONS

AND ELEVATION DRAWING

Air

Requirements:

10 cfm @ 80 psi

Electrical Requirements:

220V AC, 10 amp, 60 HZ

Shipping

Weight:

1,005 lbs.

Width:

4’ 11 1/4” (150.1 cm)

Length:

9’ 4 1/4” (285.1 cm)