MODEL #118-AAA

Dual Station Volumetric Filler / Butter Filler / Bulk Butter Filler

DESCRIPTION:

Semiautomatic dual head volumetric filler featuring continuous product flow and Sawvel’s exclusive telescopic Bottom-Up® volumetric filling. Food filling machine designed for filling butter into bulk boxes.

PERFECT FOR:

Fresh churned butter or similar product that does not seek its own level and can be supplied continuously.

CONTAINER SIZE RANGE:

- 68 lb box

- 55 lb box

- 40 lb box

- 20 lb box

CONTAINER TYPES:

- Corrugated Boxes

THIS WOULD SUIT:

- Contract Packers

- Dairies

- Small, medium, large scale independent food producers

- National food groups

- 3rd party equipment suppliers

FEATURES AND BENEFITS

Optional Model 113-CW-AAA Check Weigh Station

BENEFITS:

- Increase your production rates

- Enhance your accuracy

- Decrease your labor costs

- Full after-sales support

KEY FEATURES:

- Sawvel AAA, designed to meet or exceed 3-A®, FSMA and USDA standards

- 3/16″ stainless steel for all product contact surfaces

- Sawvel’s exclusive telescoping Bottom-Up® volumetric fill feature

- Continuous product flow

- Vertically actuated box forms set-up for quick change

- Automatic container discharge from filling station

- Easy-to-clean discharge conveyor with self tracking drive belt

- No tools needed for disassembly and clean up

- Right hand operation

- Stainless steel leveling screws

- Speeds to 7 cpm

- Stainless steel frame construction

OPTIONS AVAILABLE:

- Model 113-CW-AAA check weigh station with over / at / under target weight set points

- Stainless steel casters

- Tooling for additional size boxes

SAWVEL AAA:

This model has been designed to meet or exceed 3-A®, FSMA and USDA sanitary requirements.

- All materials rated for food contact

- Full disassembly for cleaning can be done without tools

- Elimination of flat surfaces provides excellent drainage after clean up

- Elimination of all points that could not be accessed for cleaning

SAWVEL’S EXCLUSIVE TELESCOPIC BOTTOM-UP® VOLUMETRIC FILLING:

The fill head telescopes to start filling at the bottom of the box.

The product then pushes the fill head up as it spreads into the box.

- Eliminates air pocket formation

- Every container fills to the exact same volume, no more over or under fill complaints

CONTINUOUS PRODUCT FLOW:

Product flow alternates from one side to the other as each box is filled. The supply pump does not need to stop between fill cycles.

- Reduced back pressure at the pump

- Higher production rates are possible

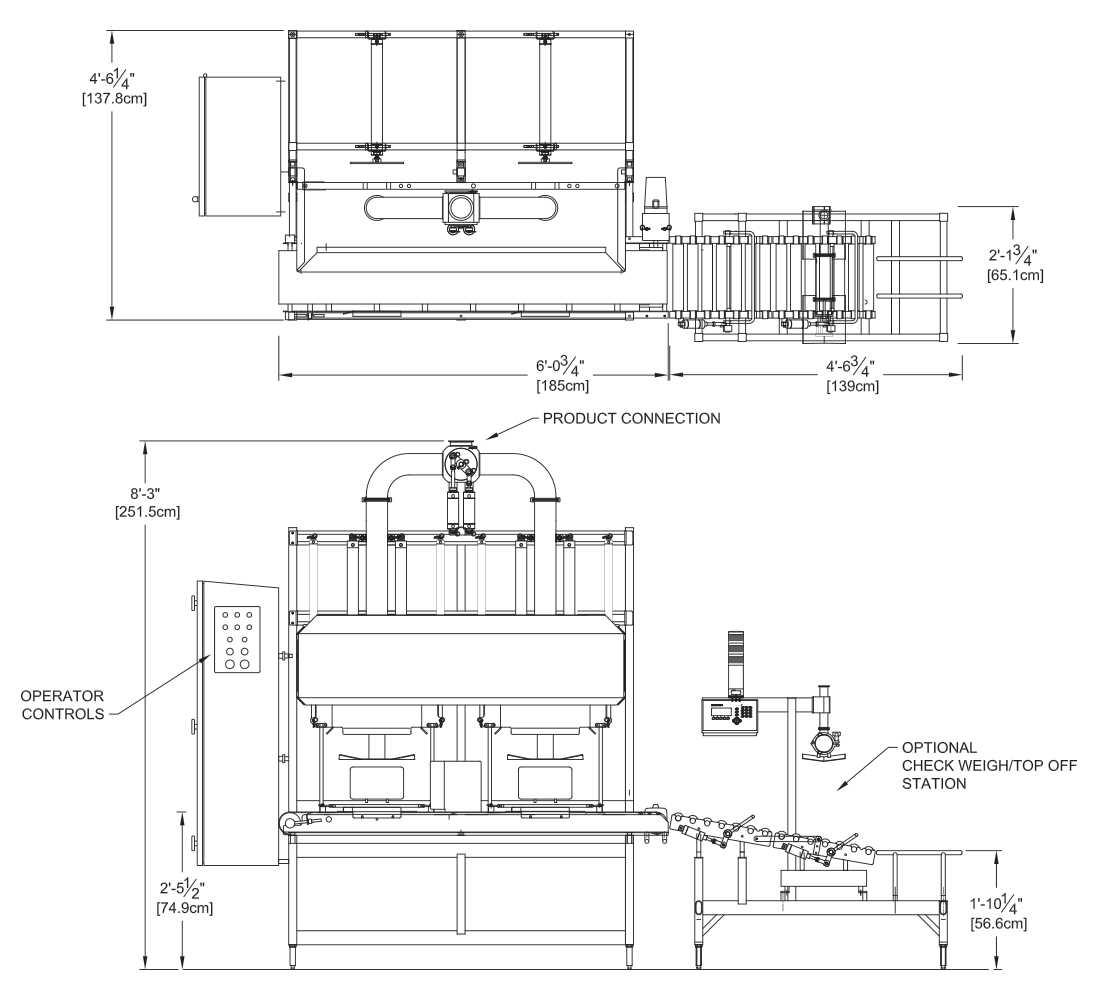

SPECIFICATIONS

AND ELEVATION DRAWING

Air

Requirements:

5 cfm @ 80 psi

Electrical Requirements:

220V AC, 18 amp, 60 Hz

Shipping

Weight:

Filler only: 1600 lbs

Width:

4’ 6.25” (137.8 cm)

Length:

Filler only: 6’ 0.75” (251.51 cm)

FREE AUTOMATION INSIGHT GUIDES

7 Ways Aging Equipment is Costing You Profits

Find out If Your Packaging Is Automation Friendly